Updated January 2026 | Tested on red oak, white ash, and hard maple

Skip this step and you will feel every raised fiber through your finish. I learned this the hard way on a dining table in 2019 – the water rings from the first dinner raised fibers right through three coats of polyurethane.

The Problem With Oak That Nobody Mentions

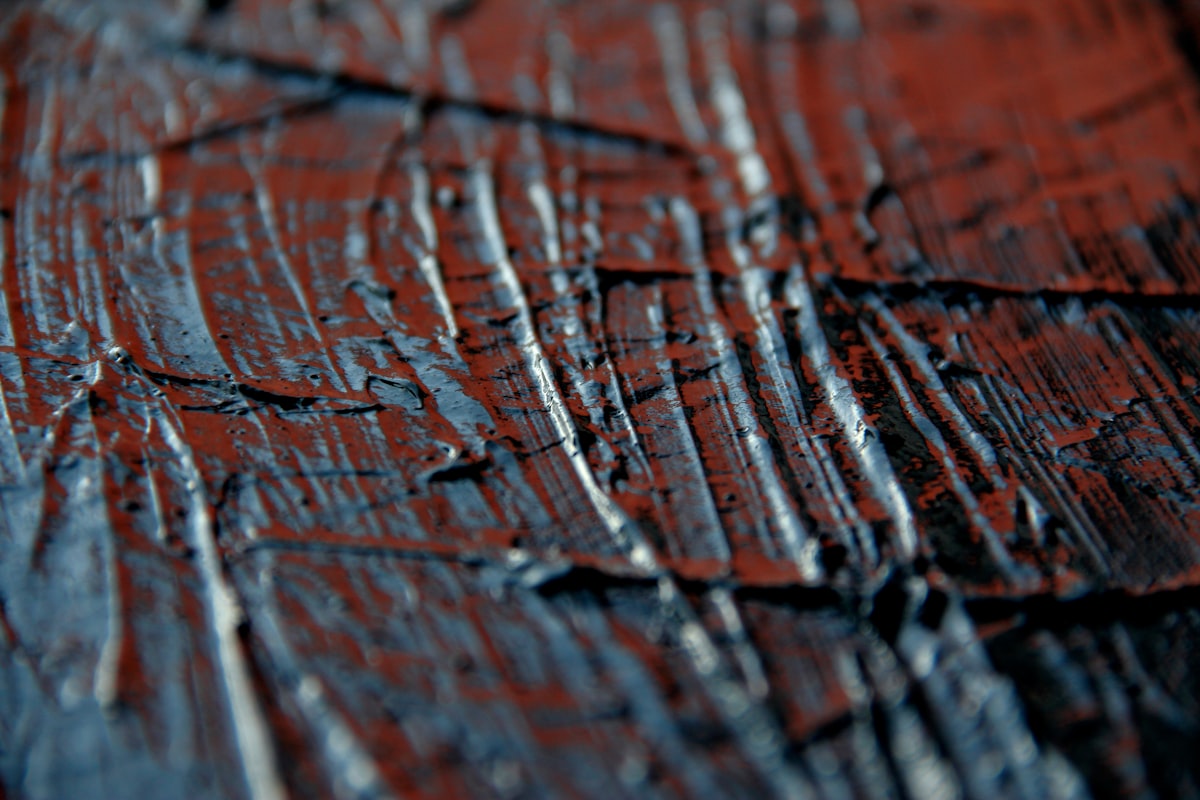

Oak has big, open pores and prominent grain patterns. It looks dramatic and feels substantial. But oak has a secret that ambushes inexperienced finishers: its grain raises aggressively when it contacts anything water-based.

Apply a water-based stain or finish directly to sanded oak, and the smooth surface you worked hard to achieve turns rough and fuzzy. Tiny wood fibers that were lying flat swell up and stand on end. Your carefully sanded surface now feels like sandpaper.

The solution seems counterintuitive: wet the wood deliberately before finishing.

Why Raising the Grain First Works

Wood fibers swell when they absorb moisture. On a freshly sanded surface, thousands of fibers are partially severed but still attached. When water hits them, they expand and stand upright.

If this happens after you’ve applied finish, those raised fibers get locked in place. You’re stuck with a rough surface under your finish coat. Sanding through the finish to fix it means starting over.

But if you raise the grain before finishing, you can sand those swollen fibers flat while the wood is still bare. When your water-based finish goes on later, most fibers have already swelled and been removed. The surface stays smooth.

The Professional Technique

Step 1: Final sanding. Sand your oak to your final grit—typically 150 for staining or 180 for clear finishing. Remove all sanding dust thoroughly.

Step 2: Wet the surface. Using a clean cloth dampened with distilled water, wipe the entire surface evenly. You want the wood damp but not soaking. The surface should darken from moisture without pooling.

Step 3: Let it dry completely. This is critical. In normal conditions, 4-6 hours works. In humid environments, wait overnight. The wood must return to its original moisture content before proceeding.

Step 4: Sand away raised fibers. Using one grit finer than your final pre-raising grit (180 if you sanded to 150 originally), lightly sand the entire surface. The raised fibers will sand off easily—you’ll feel the surface transform from rough to smooth as you work.

Step 5: Remove dust. Vacuum, then wipe with a tack cloth. Now your oak is ready for water-based stain or finish with minimal additional grain raising.

Why Distilled Water Matters

Tap water contains minerals and chlorine that can leave residue or react with certain finishes. Distilled water is pure—nothing left behind when it evaporates. For the small amount needed for grain raising, a gallon of distilled water from any grocery store lasts through dozens of projects.

Repeat the Process for Extra Smoothness

For furniture-grade work, I often raise the grain twice. After the first raise-and-sand cycle, I repeat the process. The second raising causes much less fiber swelling than the first, but sanding it away leaves an even smoother surface.

Two cycles of raising virtually eliminate the problem on oak, ash, and other open-pored woods. Your final finish goes on smoothly without surprises.

Which Woods Benefit Most

High benefit: Oak (red and white), ash, elm, hickory—any wood with large pores and prominent grain.

Moderate benefit: Walnut, mahogany, cherry—medium-pored woods that still show some grain raising.

Minimal benefit: Maple, birch, poplar—tight-grained woods with less raising tendency. Still worth doing for water-based finishes, but less dramatic difference.

When to Skip This Step

If you’re using exclusively oil-based stains and finishes, grain raising isn’t a concern. Oil doesn’t swell wood fibers the way water does. The technique specifically addresses water-based product use.

However, even oil finish users may want to raise the grain once. Many woodworkers use water-based wood glue, which can cause localized grain raising around joints. Pre-raising ensures your final finish looks consistent across glued and unglued areas.

The Time Investment Pays Off

Raising the grain adds half a day to your finishing schedule—time for wetting, drying, and sanding. But compare that to the time required to sand through a finish coat and start over after unexpected grain raising ruins your work.

Professional finishers raise the grain automatically on any project destined for water-based products. The few hours of prevention eliminate the possibility of a major problem. Once you’ve experienced the difference between raised-and-sanded oak versus oak finished directly, you’ll never skip this step on open-pored woods again.