Best Outdoor Wood Finish has gotten complicated with all the options and conflicting advice flying around. As someone who has spent years working with wood finishes in my own shop, I learned everything there is to know about this subject. Today, I will share it all with you.

Best Outdoor Wood Finish

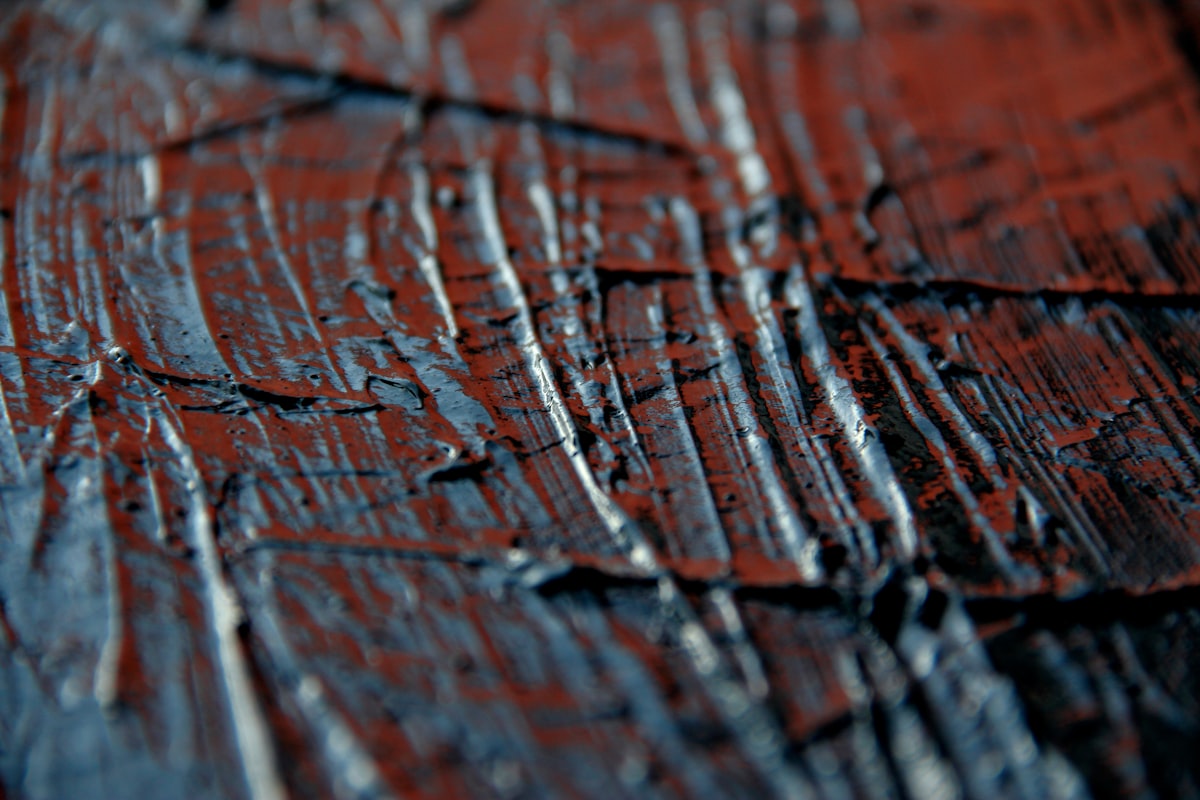

Outdoor wood furniture and structures face a range of challenges. From harsh sun rays to heavy rain, the elements can be unforgiving. To extend the life of your outdoor wood pieces, choosing the right finish is crucial. Different finishes offer varying levels of protection and aesthetic benefits.

Types of Outdoor Wood Finishes

Probably should have led with this section, honestly.

Several types of finishes are suitable for outdoor use. Each type has unique characteristics and benefits. Knowing the differences can help you make the best choice.

Oil-Based Finishes

Oil-based finishes penetrate the wood surface, providing deep protection. They enhance the natural beauty of the wood grain. Linseed oil and tung oil are popular — and that is what makes this endearing to us woodworkers choices. While offering a beautiful finish, these oils may require frequent reapplication to maintain their protective properties.

- Linseed Oil: Derived from flax seeds, it deeply nourishes the wood. However, it can take longer to dry, requiring patience. Regular maintenance is needed for optimal protection.

- Tung Oil: Obtained from tung tree nuts, it creates a protective barrier. It provides excellent water resistance. Tung oil takes time to cure but offers better durability compared to linseed oil.

Water-Based Finishes

Water-based finishes are eco-friendly and dry quickly. They offer protection against UV rays and moisture. Unlike oil-based options, they don’t deepen the wood color as much. However, they can provide a clear finish.

- Water-Based Polyurethane: This finish forms a hard, transparent shell. It’s resistant to scratches and UV damage. However, it may need recoating every couple of years in harsh weather conditions.

Spar Varnish

Spar varnish is a popular choice for marine applications. It is flexible and can expand and contract with the wood. This is essential for outdoor furniture exposed to variable weather conditions. It blends oils for flexibility with UV-blocking agents for durability.

Spar varnish requires multiple coats for the best protection. Some formulations have high VOCs (Volatile Organic Compounds), so consider ventilation and environmental concerns when using it.

Stains and Seals

Stains and seals combine color and protection. Stains penetrate while adding pigment, whereas seals form a surface barrier.

- Wood Stains: Available in oil or water-based formulas. They enhance and enrich the wood’s color. Stains can offer some sun protection but often require additional sealants.

- Sealants: Clear sealants provide a protective layer against moisture. They are often applied over stains for extra durability. Multiple coats may be necessary to maximize protection.

Factors to Consider

Choosing the best finish depends on several factors, such as climate, wood type, and the specific needs of the item.

Climate

In areas with high humidity, finishes that offer superior moisture protection are essential. Oil-based or marine-grade varnishes are good choices. In dry, sunny locations, UV protection is crucial, making spar varnish or UV-resistant polyurethane ideal.

Wood Type

Some woods, like teak or cedar, contain natural oils that resist decay. These types might not need as heavy finishes, allowing simpler treatments. However, softer woods, such as pine, may require a more comprehensive protective layer to avoid damage from the elements.

Application and Maintenance

Ease of application and maintenance frequency affect user satisfaction. An oil finish might be easy to apply but needs regular maintenance. Meanwhile, polyurethane might be tougher to apply but lasts longer without requiring attention. Consider the time and effort you are willing to invest.

Step-by-Step Application Tips

Preparation

Start by sanding the wood surface. Use medium-grit sandpaper for the first pass, then fine-grit for a smooth finish. Ensure the wood is clean and dry before applying any finish. Dust particles, oils, or moisture can impede finish adhesion.

Application

- Read the product label for specific instructions.

- Use a high-quality brush for even application. Foam brushes work well for polyurethane.

- Apply in thin, even coats. Thick coats might peel or bubble over time.

- Allow adequate drying time between layers. Temperature and humidity affect drying times.

Maintenance

Inspect outdoor wood regularly. Look for signs of wear, such as fading or peeling. Touch up areas as needed. Periodically reapply the chosen finish to maintain protection and appearance. Regular cleaning can also prolong the lifespan of the finish. Use mild soap and water; avoid abrasive cleaners.

Popular Brands and Products

Some brands have established themselves as leaders in outdoor finishes. Consider their reputation and specific products that fit your needs.

- Minwax Helmsman Spar Urethane: Popular for its water and UV resistance. Its finish remains clear without yellowing over time.

- Thompson’s WaterSeal: Known for penetrating sealants ahead of its time. It provides a robust barrier against moisture.

- Cabot Australian Timber Oil: Highly regarded for use on dense woods like mahogany and teak. It combines penetrating oils for maximum protection.

Environmental and Safety Considerations

When choosing a finish, consider its impact on the environment. Many finishes contain VOCs, which can harm air quality. Opt for low-VOC or water-based products when possible. Ensure proper ventilation during application to minimize health risks. Dispose of materials, such as brushes and rags, according to local regulations.

The world of outdoor wood finishes offers a variety of solutions. Understand the strengths and weaknesses of each to make an informed choice. Protecting your wood investments will not only extend their life but also enhance their beauty.

Recommended Woodworking Tools

HURRICANE 4-Piece Wood Chisel Set – $13.99

CR-V steel beveled edge blades for precision carving.

GREBSTK 4-Piece Wood Chisel Set – $13.98

Sharp bevel edge bench chisels for woodworking.

As an Amazon Associate, we earn from qualifying purchases.