Best Finish for Outdoor Wood Table

Finishing outdoor wood tables has gotten complicated with all the product options and contradictory advice flying around. As someone who’s had three different outdoor tables over the past decade — and refinished each one at least twice — I learned everything there is to know about what actually holds up outside. Today, I will share it all with you.

Understanding the Basics

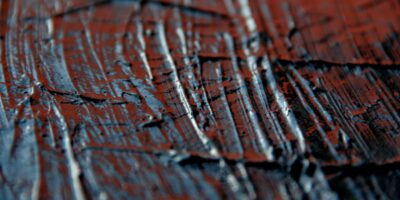

Here’s the reality: your outdoor table is getting hit by sun, rain, humidity swings, and temperature changes every single day. The finish you put on it is the only thing standing between that beautiful wood and a gray, cracked mess. I learned this lesson when my first outdoor table — an unfinished cedar piece I was so proud of — turned gray and started splitting within one season.

Types of Finishes

Probably should have led with this section, honestly. Wood finishes break down into two main categories: penetrating finishes and surface finishes. Both work, but they work very differently.

Penetrating Finishes

That’s what makes penetrating finishes endearing to us outdoor furniture builders — they soak right into the wood and protect from the inside out. No film on top means nothing to peel or crack. The wood still looks and feels like wood.

Tung Oil

- Tung oil comes from the seeds of the tung tree. It’s a popular choice for those desiring a natural appearance.

- The oil penetrates deep into the wood and hardens, providing water resistance.

- Multiple coats are usually necessary for optimal protection.

Linseed Oil

- Linseed oil, derived from flax seeds, is another traditional choice.

- It penetrates well but tends to darken over time.

- Boiled linseed oil dries faster than raw, making it more practical for furniture.

While oils give you that gorgeous natural look, they do need refreshing roughly once a year. I’ve gotten into the habit of doing mine every spring — takes about twenty minutes per table and has become kind of a seasonal ritual at this point.

Surface Finishes

Surface finishes create a protective layer on the wood. They are generally more durable than penetrating finishes and provide greater resistance to scratches and spills.

Varnish

- Varnish is a traditional choice for outdoor furniture. It is tough and durable.

- Offers excellent protection against water and UV rays.

- Requires sanding between coats to ensure a smooth finish.

Polyurethane

- Polyurethane forms a hard, protective barrier. Known for its durability.

- Available in oil-based and water-based formulations.

- Water-based polyurethane is less odorous and dries quickly, making it popular for home use.

Lacquer

- Lacquer is usually a less common choice for outdoor furniture but offers a high-gloss finish.

- It’s quick drying and gives a durable coat.

- Not as UV resistant as varnish or polyurethane, so less ideal for high-exposure areas.

Specialty Finishes

For those looking for advanced protection and aesthetics, several specialty finishes cater to outdoor needs.

Epoxy

- Epoxy is a highly durable finish often used for tabletops due to its water and chemical resistance.

- Forms a thick, clear coat that locks out moisture.

- Needs UV protection topcoat as epoxy alone can yellow with sun exposure.

Marine Spar Varnish

- Originally formulated for boats, spar varnish is excellent for outdoor furniture.

- Provides superior flexibility and resistance to harsh weather conditions.

- More elastic than traditional varnishes, allowing wood to expand and contract.

Application Tips

Applying finishes requires some technique and patience. Following correct procedures ensures longevity and effectiveness of the finish.

- Thoroughly clean and sand the table before applying any finish. This removes dirt and smooths the surface for even application.

- Apply the finish using a brush or cloth, following the grain of the wood. This helps achieve an even coat.

- For penetrating oils, allow the finish to absorb fully. Wipe off the excess before it becomes tacky.

- For surface finishes, multiple thin coats are preferable to one thick coat. Sand lightly between coats for a smooth finish.

- Consider environmental conditions like humidity and temperature, which can affect drying times.

Maintenance

Regular maintenance is key to extending the life of your outdoor wood table. Different finishes require varying levels of upkeep.

- Oiled finishes need regular reapplication, often every year, to maintain protection and appearance.

- Surface finishes like polyurethane and varnish need touch-ups at signs of wear or damage.

- Check for signs of peeling or cracking, and re-sand and refinish as necessary to prevent further damage.

Environmental Considerations

Choosing sustainable and environmentally friendly finishes is increasingly important. Consider water-based options to reduce volatile organic compounds (VOCs).

- Water-based polyurethane offers a lower VOC option compared to oil-based versions.

- Plant-based oils like walnut and soybean can be alternatives to traditional linseed or tung oils.

- Eco-friendly brands provide extensive ranges of low-impact finishes.

“`