My Quest to Find a Table Finish That Actually Lasts has gotten complicated with all the options and conflicting advice flying around. As someone who has spent years working with wood finishes in my own shop, I learned everything there is to know about this subject. Today, I will share it all with you.

My Quest to Find a Table Finish That Actually Lasts

Probably should have led with this section, honestly.

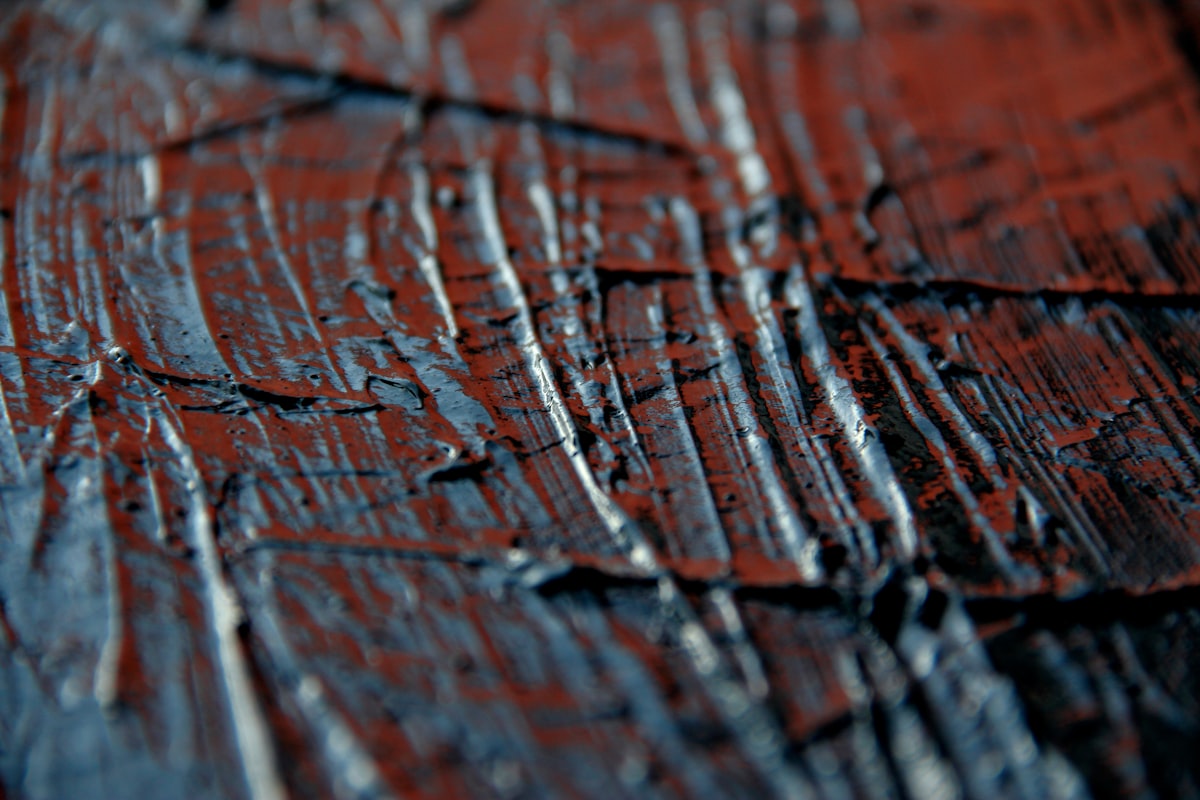

Tables take a beating. I learned this the hard way when the first dining table I built developed water rings after about a month. Then heat marks from coffee mugs. Then scratches from who knows what. It looked like it had been through a war.

That table taught me that choosing a finish is not just about how it looks – it is about how much abuse the surface can take. Here is what I have figured out over the years.

The Two Basic Categories

Finishes either soak into the wood (penetrating) or sit on top (film-forming). For tables that see real use, this matters more than you might think.

Penetrating finishes like oils feel more natural. The wood still has texture. But they offer less protection against spills and heat. Every time your kid sets down a wet glass, you are gambling.

Film finishes like polyurethane create a barrier. They can feel plastic-y if overdone, but they shrug off abuse that would destroy an oil finish.

For most tables, I lean toward film finishes now. The natural look is nice, but so is not refinishing every year.

Polyurethane: The Workhorse

Oil-based polyurethane is probably the most durable readily-available finish for tables. It builds up a tough protective layer that handles heat, moisture, and scratches pretty well.

The downside: it yellows over time. On dark woods, no big deal. On light woods or white paint, it can look off after a few years. It also takes forever to fully cure and stinks while drying.

Water-based poly is clearer and dries faster, but it is not quite as tough in my experience. I use it on pieces where appearance matters more than durability.

Lacquer: Fast But Tricky

Lacquer dries in minutes instead of hours, which is amazing. And it sprays beautifully – furniture factory smooth if you know what you are doing.

But it is sensitive. Heat and alcohol can damage it. A hot pizza box or a spilled drink can leave marks. I use lacquer on pieces that will be treated gently, not on everyday tables.

It also requires spray equipment and good ventilation. The fumes are no joke.

Varnish: Old School Tough

Traditional varnish (not the stuff labeled varnish at hardware stores, which is often polyurethane) is flexible and incredibly durable. Marine varnish especially. This stuff protects boats from salt water, so your coffee table should be fine.

Application is slower. Drying takes longer. But the final result is beautiful and long-lasting. I use spar varnish on outdoor tables and anything near windows with sun exposure.

The Oil Options

Tung and linseed oil create a more natural look and feel. The wood still feels like wood under your hands. For a casual table that will not see heavy abuse, they work fine.

But be realistic about maintenance. Oil finishes need refreshing – maybe every few months for a dining table. Water and heat will leave marks if you are not careful. Coasters become mandatory.

I finished a coffee table with tung oil once because I loved the look. It was beautiful. For about six months. Then it looked tired and I had to refinish it. Now that table has polyurethane.

Matching Finish to Table Use

Dining tables: These get daily abuse. Polyurethane or conversion varnish if you can spray it. Water-based is fine if you want to avoid yellowing.

Coffee tables: Hot drinks, cold drinks, feet, magazines, remote controls. You need something durable. Poly or lacquer with coasters as a backup plan.

Side tables: Usually lighter use. Oil finishes can work here if you want the natural look. Just accept that lamp rings and water marks might happen.

Outdoor tables: Marine varnish or outdoor-rated poly. Reapply yearly or whenever it starts looking rough. Weather is hard on wood.

My Actual Process

For most tables, I sand to 220 grit, wipe with a tack cloth, and apply 3-4 coats of water-based polyurethane. Light sanding between coats with 320 or 400. Let it cure for at least a week before regular use.

If I want a bit of color, I stain first and let that dry completely before poly. Rushing causes problems.

For oil finishes, I do multiple thin coats over several days. Then I tell the recipient to use coasters and cross my fingers.

When Things Go Wrong

Finishes can be fixed. Water rings can often be rubbed out with paste wax and 0000 steel wool. Deep scratches might need local sanding and touch-up.

For really messed up tables, stripping and refinishing is always an option. I have done it more times than I would like. Not fun, but better than living with an ugly table.

The key is picking an appropriate finish upfront and setting realistic expectations about maintenance. No finish is permanent. Wood is organic material that needs care.

Recommended Woodworking Tools

HURRICANE 4-Piece Wood Chisel Set

CR-V steel beveled edge blades for precision carving.

GREBSTK 4-Piece Wood Chisel Set

Sharp bevel edge bench chisels for woodworking.

As an Amazon Associate, we earn from qualifying purchases.