Table Finish: A Comprehensive Guide has gotten complicated with all the options and conflicting advice flying around. As someone who has spent years working with wood finishes in my own shop, I learned everything there is to know about this subject. Today, I will share it all with you.

Table Finish: A Comprehensive Guide

Tables are important — probably should have led with this, honestly furniture pieces in homes, offices, and public spaces. The finish of a table affects its appearance, durability, and feel. Understanding different types of finishes and their application contributes significantly to the longevity and beauty of the table.

Types of Table Finishes

Probably should have led with this section, honestly.

Various finishes are used to enhance tables. Each serves a specific purpose, providing protection or aesthetic appeal. The choice depends on factors like table usage, wood type, and personal preference.

Oil Finishes

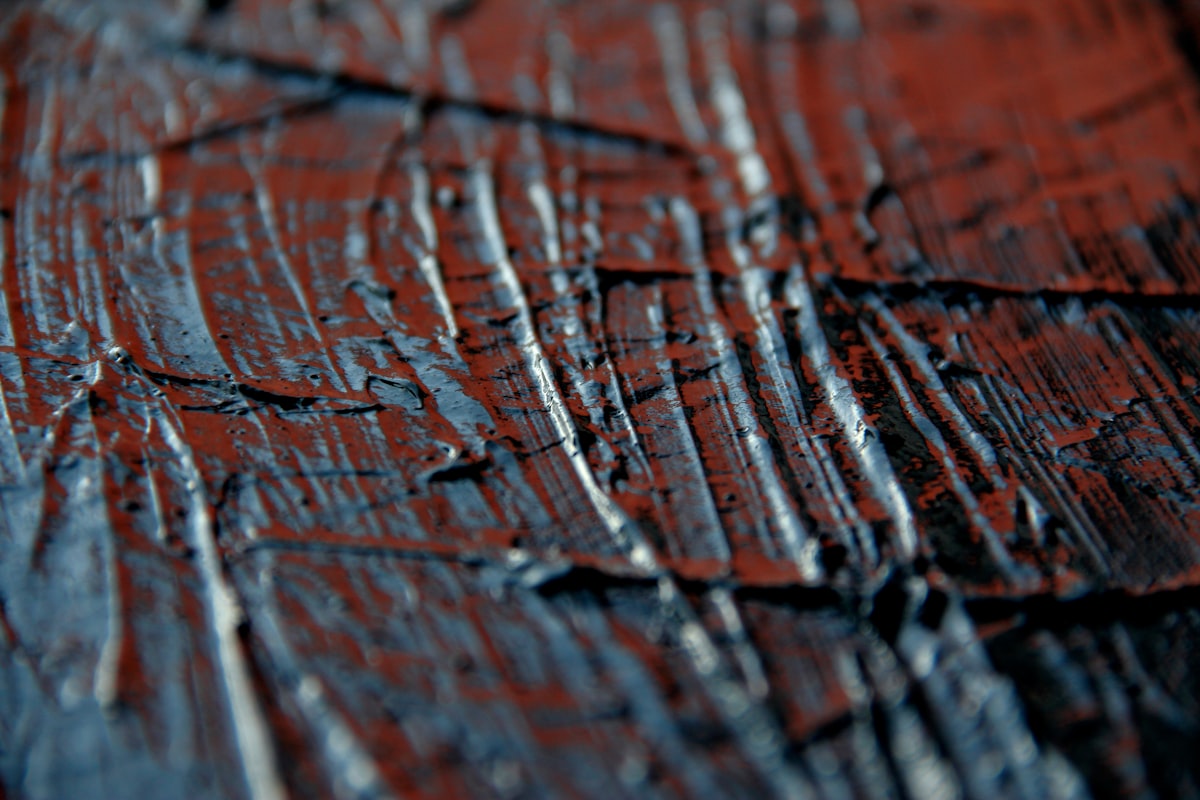

Oil finishes penetrate the wood. They provide a natural look and feel. Tung oil and linseed oil are popular — and that is what makes this endearing to us woodworkers. These finishes enhance wood grain and offer some protection. Regular maintenance involves reapplying oil to maintain luster and protection.

Varnish

Varnish adds a durable, glossy coating. It is resistant to heat, chemicals, and water. Varnish comes in various sheens from matte to high-gloss. It is suitable for dining and kitchen tables. Application requires careful sanding and multiple layers.

Lacquer

Lacquer creates a shiny, hard surface. It’s applied in thin layers and dries quickly. Lacquer is durable against scratches and moderately resistant to spills. It works well for modern or oriental-style tables. Spraying is a common method of application.

Polyurethane

Polyurethane varnish offers strong resistance to moisture, heat, and chemicals. It can be water-based or oil-based. Water-based polyurethane is clear and fast-drying. Oil-based provides a golden tone, enhancing wood warmth. Polyurethane is versatile and suitable for high-traffic areas.

Shellac

Shellac is a natural resin that gives a warm tone to wood. It’s less durable than polyurethane or lacquer but easier to repair. It’s applied with a brush or cloth. Shellac works for furniture with less exposure to moisture and heat.

Wax

Wax finishes are often used in combination with other finishes. They provide a soft, matte sheen and are easy to apply. Waxes are suitable for tables with decorative or artistic elements. They offer minimal protection and require regular reapplication.

Choosing the Right Finish

The right finish depends on several factors. Consider the table’s location, usage, and style. Dining tables in busy households need durable finishes like polyurethane or varnish. Decorative tables may benefit from wax or oil finishes for aesthetic purposes.

Location

- Indoor tables: Indoor tables have more flexibility with finishes. Choose based on traffic and exposure to sunlight or potential spills.

- Outdoor tables: Outdoor tables need protection from elements. Polyurethane and marine varnish are ideal for their resistance to moisture and UV rays.

Wood Type

Different woods react differently to finishes. Softwoods like pine benefit from more protective finishes. Hardwoods like oak and walnut show more grain character, making oil finishes appealing. Ensure the finish complements and protects the specific wood type.

Intended Use

- Dining tables: Require durable, water-resistant finishes. Polyurethane or varnish are practical choices.

- Coffee tables: A lacquer or oil finish may suffice, offering a balance between durability and aesthetics.

- Occasional tables: Wax or shellac provides suitable protection and sheen for tables with infrequent use.

Application Tips

Proper application is crucial for a smooth, attractive finish. Each product has specific instructions, but general practices improve results across all types.

Surface Preparation

Start with a smooth surface. Sand the table thoroughly, starting with coarse grit paper and progressing to finer grits. Clean the surface to remove all dust and debris. This ensures the finish bonds properly with the wood.

Application Techniques

Choose the right tools. Brushes, cloths, and sprayers each have distinct advantages. Brushes provide control, cloths work well with oils, and sprayers are suitable for even lacquer coats. Apply the finish in thin, even layers. Allow enough drying time between coats to avoid texture issues.

Safety Precautions

Many finishes contain volatile substances. Work in a well-ventilated area. Use appropriate respiratory protection if necessary. Follow manufacturer’s guidelines for safe handling and disposal.

Maintenance and Care

Regular maintenance extends the life and appearance of a table finish. Each finish requires specific care routines.

Cleaning

Avoid harsh chemicals that damage the finish. Use a damp cloth with mild soap. For tougher stains, specialized cleaners designed for the specific finish are advisable.

Polishing

Occasional polishing enhances the finish. Use appropriate products that won’t strip the existing finish. Maintain a schedule to prevent buildup or dullness.

Repair

- Scratches: Minor scratches can be buffed out or filled with wax sticks matching the wood color.

- Water marks: Light water marks can often be lifted with gentle heat, such as a warm iron over a cloth.

- Reapplication: Over time, finishes may wear. Some finishes, like oil or wax, need regular reapplication for best results.

Common Mistakes to Avoid

Avoid common pitfalls to achieve the best results in table finishing projects. Prepare, apply, and maintain finishes with care.

Poor Preparation

Rushing surface preparation often leads to poor finish adhesion. Inadequate sanding or cleaning results in uneven surfaces or peeling finishes.

Over-application

Applying too much finish at once creates drips, runs, and unevenness. Thin layers applied slowly achieve smooth results.

Ignoring Manufacturer’s Instructions

Each product has unique application and drying requirements. Ignoring instructions may cause curing issues or reduced durability.

Exploring Eco-friendly Finishes

Concern about environmental impact leads to interest in eco-friendly finishes. These options balance performance with sustainability.

Water-Based Finishes

Water-based finishes emit fewer VOCs than traditional solvent-based products. They are easier to clean up and offer similar durability with minimal environmental impact.

Natural Oils and Waxes

These products, like tung oil and bee wax, minimize chemical processing. They come from renewable resources and offer completely biodegradable finishes.

Low-VOC Varnishes and Lacquers

Brands develop low-VOC versions of traditional finishes. They maintain protective qualities while reducing harmful emissions during application and drying.

Recommended Woodworking Tools

HURRICANE 4-Piece Wood Chisel Set – $13.99

CR-V steel beveled edge blades for precision carving.

GREBSTK 4-Piece Wood Chisel Set – $13.98

Sharp bevel edge bench chisels for woodworking.

As an Amazon Associate, we earn from qualifying purchases.