Using tung oil on kitchen projects has gotten complicated with all the confusing labeling and contradictory safety claims flying around. As someone who accidentally made a paint-thinner-flavored salad with the wrong product, I learned everything there is to know about tung oil and food safety. Today, I will share it all with you.

Tung Oil on Kitchen Projects: What I Wish Someone Told Me

Three years ago I finished a salad bowl with something I thought was pure tung oil. Turns out it was not, and my wife said the first salad we ate from it tasted like paint thinner. We threw out the salad and I spent the next month researching what went wrong.

So here is everything I have learned about tung oil and food safety, because this stuff is confusing and the labeling is often misleading.

What Tung Oil Actually Is

Real tung oil comes from the nuts of the tung tree, which grows mostly in China. It has been used for centuries – like, thousands of years. The Chinese used it to waterproof boats and furniture way before anyone was selling it at Home Depot.

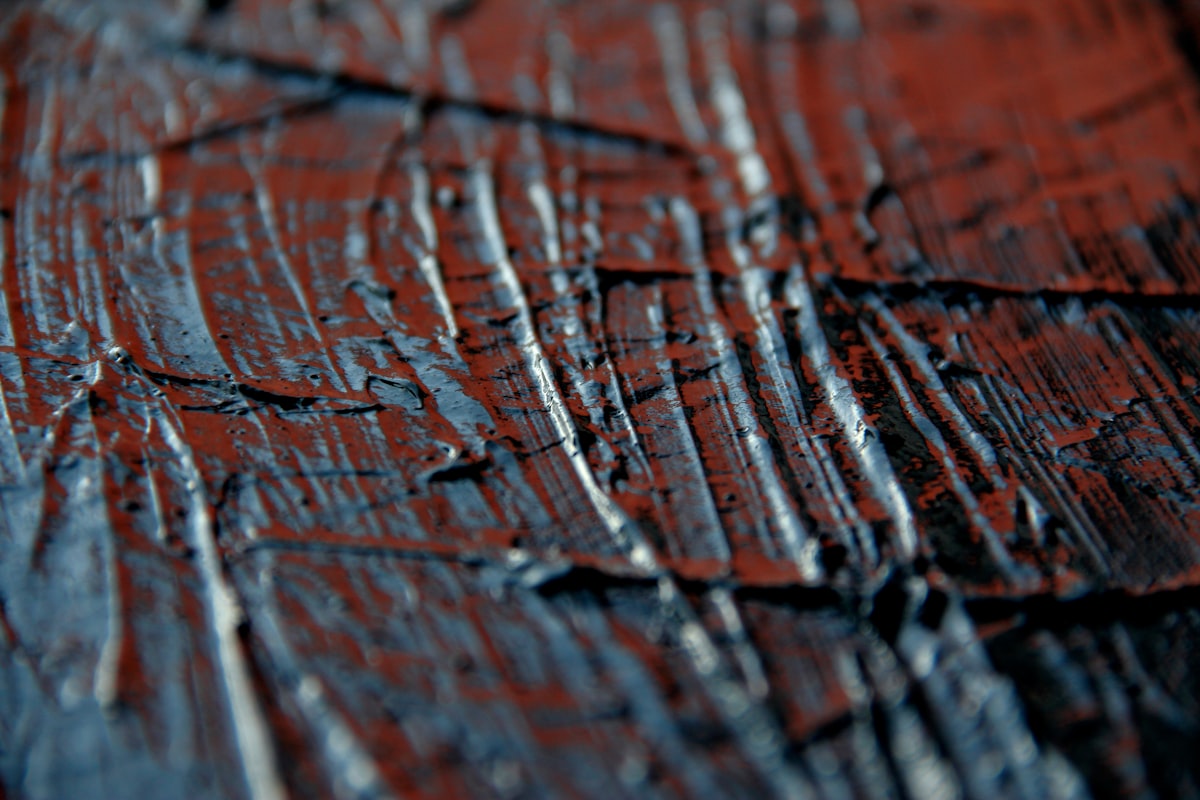

Pure tung oil soaks into wood and hardens through a chemical reaction with oxygen. It does not just sit on top like paint. This is what makes it so good for projects that get used and touched. The finish becomes part of the wood itself.

The problem is that what gets sold as tung oil often is not pure tung oil at all. And that is where people like past-me get into trouble.

The Label Reading Problem

Here is what drove me crazy. Probably should have led with this section, honestly when I started researching this: a product can be called tung oil finish or tung oil blend even if it contains almost no actual tung oil.

Those blends usually contain varnish, petroleum distillates, or other solvents. They dry faster and are easier to apply, which is why manufacturers like them. But they are absolutely not food safe, even after they cure.

Pure tung oil, when fully cured, is food safe. But you need to actually get the pure stuff, and you need to wait for it to cure completely. Both parts matter.

How to Tell What You Have

Pure tung oil will say 100% pure tung oil on the label. Nothing else. If it says tung oil finish, tung oil varnish, tung oil blend, or anything with modifiers, it is not pure.

Pure tung oil also has a characteristic smell – kind of nutty and not unpleasant. The fake stuff smells like chemicals because, well, it is chemicals.

Finally, pure tung oil is expensive. If you are getting a gallon for fifteen bucks, you are not getting pure tung oil. The real stuff runs $30-50 for a quart, sometimes more.

The Curing Thing

This is the part that trips people up. Pure tung oil needs time to cure – and I mean really cure, not just dry to the touch.

Surface drying happens in a day or two. But the oil keeps reacting with oxygen for weeks after that. Full cure takes somewhere between two and four weeks depending on temperature, humidity, and how thick you applied it.

During this curing period, the finish can still leave a taste or smell on food. Not dangerous at this point, but unpleasant. This is why you need to wait the full cure time before using anything you finished with tung oil in the kitchen.

I usually wait a full month to be safe. Yeah, it requires patience. But I would rather wait than have another paint thinner salad incident.

How I Apply Tung Oil Now

My process has evolved a lot since that first disaster.

I thin the first coat with citrus solvent – about 50/50. This helps it soak in deeper. Some people use mineral spirits, but I prefer citrus because it evaporates cleaner and smells better.

Apply with a clean rag, working it into the wood. Let it soak for 30 minutes, then wipe off every bit of excess. If you leave pools of oil on the surface, they will get gummy and never cure properly.

Wait 24 hours, then apply another coat, this time maybe 75% oil to 25% solvent. Same process – apply, wait, wipe.

Third coat is usually pure oil. By now the wood is pretty saturated so it will not soak in as much.

Then I wait. And wait. And wait some more. A month minimum before it touches food.

Why Bother With Tung Oil At All

After all this hassle, you might wonder why I still use the stuff. Fair question.

The finish is gorgeous. Tung oil brings out wood grain like nothing else. It gives this warm, natural glow that you just do not get from synthetic finishes.

It is durable once cured. That’s what makes real tung oil endearing to us woodworkers who build kitchen pieces. Water resistant, does not scratch easily, and actually gets better looking with age and use.

It is genuinely food safe when done right. No worrying about chemicals leaching into your salad.

And it is repairable. If you scratch it or the finish wears in a spot, just sand lightly and apply more oil. Try that with polyurethane.

When I Use Something Else

Tung oil is not my go-to for everything food-related. For cutting boards and heavily used items, I usually just use mineral oil. It is simpler, faster, and foolproof. No cure time needed.

For serving boards and bowls that will see light use, tung oil is perfect. The extra effort pays off in how beautiful the finish looks.

For anything my kids might use, mineral oil and beeswax. They are not patient enough to wait a month for anything.

The Bottom Line

Tung oil is food safe when you use the pure stuff and let it cure properly. The key words are pure and cure.

Read labels carefully. Spend the money on real tung oil. Wait longer than you think you need to. Follow those rules and you will be fine. Ignore them and you might end up with a salad that tastes like a hardware store, which I can tell you from experience is not a great dinner party moment.