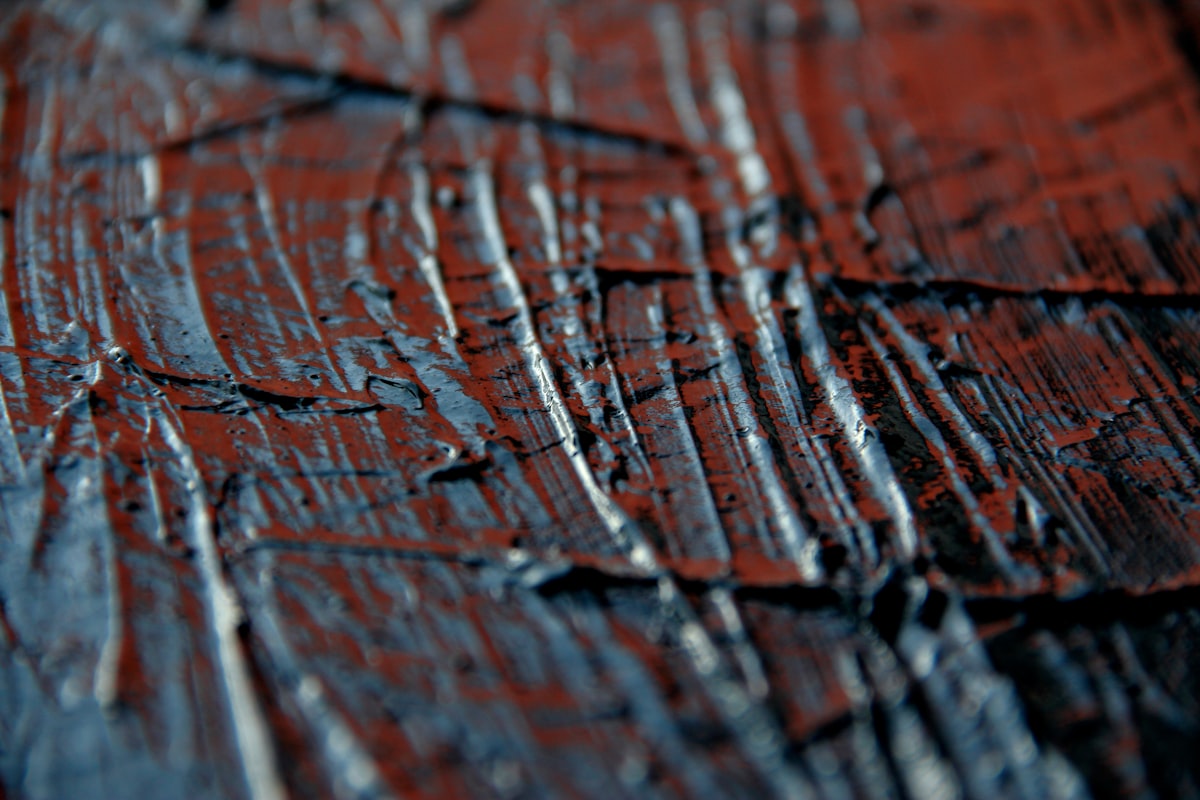

Understanding Fumed Oak Finish

Fumed oak finish refers to a specific wood treatment process that enhances the natural beauty of oak wood by altering its color and grain patterns. This method involves the use of ammonia fumes, a technique that originated in the late 19th century. The fuming process brings out the rich tones and distinctive patterns in oak, making it highly desirable for furniture, flooring, and millwork.

The Fuming Process

Fuming wood requires placing it in an enclosed environment where it’s exposed to ammonia fumes. These fumes react with the natural tannins in the wood, affecting its color. The longer the wood is exposed, the more pronounced the effect. This process results in various shades of brown, from light to dark, depending on the duration of exposure and the oak’s tannin content.

Initially, craftsmen used this method to create a weathered look reminiscent of older oak furniture. The process can take several hours or even days, with the time varying based on the desired final appearance. It’s crucial to monitor the pieces closely to avoid over-fuming, which can lead to an overly dark or uneven finish.

Historical Context

The origin of fumed oak can be traced back to the Arts and Crafts movement. During this period, the craftsmanship and natural materials were paramount. Furniture makers sought to move away from heavily varnished finishes to something more understated and natural. Fuming helped achieve this more organic look. This method gained popularity in England and America during the early 20th century, becoming a staple in both residential and commercial settings.

Benefits of Fumed Oak

One of the primary advantages of fumed oak is its enhanced aesthetic appeal. The process accentuates the wood’s grain, giving it depth and character. This appeals to those who appreciate the natural beauty of wood. Fumed finishes are unique. No two pieces are identical, providing a bespoke element to furniture and woodwork. Additionally, the treatment slightly hardens the wood, adding to its durability.

The process also has practical benefits. Fumed oak tends to resist fading better compared to other finishing techniques. The color doesn’t just sit on the surface but penetrates the wood, making the finish more enduring. It doesn’t require frequent re-finishing, allowing owners to enjoy their wood items with minimal maintenance.

Environmental Considerations

While fuming with ammonia is effective, it’s essential to consider the environmental impact. Historically, ammonia was used liberally without adequate safety measures. Today, the process complies with strict safety and environmental guidelines. Modern fuming uses controlled environments to minimize exposure and environmental impact, ensuring both worker safety and adherence to environmental standards.

Alternatives to traditional ammonia fuming are available. Water-based tinted finishes mimic the appearance of fumed oak without using ammonia. While this maintains a similar aesthetic, purists may find that these alternatives lack the depth that true fuming provides.

Fumed Oak Applications

Fumed oak is prevalent in furniture making. Tables, chairs, cabinets, and flooring are popular items crafted from this material. Craftsmen prefer fumed oak for pieces meant to be statement items. Large tables or feature walls are examples of where fumed oak’s dramatic appearance can be used effectively.

Fumed oak is also favored in upscale interior design. Architects and designers specify it for high-end residential and commercial projects where unique and lasting materials are desired. It complements both traditional and contemporary styles, adapting to various design philosophies.

Maintenance Tips

Proper care of fumed oak is vital to maintain its beauty. Regular dusting helps prevent dirt buildup. Use a soft, dry cloth to clean the surface. Avoid direct sunlight to prevent any color alterations. Occasionally, reapply a protective wax or oil to nourish the wood and keep it looking rich. Although durable, fumed oak surfaces can scratch. Use coasters and placemats to protect them from heavy or rough objects.

Caring for Fumed Oak

Fumed oak’s maintenance is similar to other high-quality wood finishes. Spot cleaning spills promptly will prevent any potential staining. Understanding that wood is a living material helps in its preservation. Changes in temperature and humidity can affect the wood’s shape, so maintaining a consistent environment is beneficial.

For significant maintenance needs, consulting a professional is advisable. They can guide on deep cleaning or refinishing services if necessary. Employing experts ensures that the fumed oak’s distinctive qualities are preserved.

Concluding Thoughts

Fumed oak’s allure lies in its ability to transform simple oak into a piece of art. Its application spans several decades, proving the lasting appeal of this unique finish. Understanding its history, benefits, and care ensures that the charm of fumed oak continues to grace interiors worldwide.

Recommended Woodworking Tools

HURRICANE 4-Piece Wood Chisel Set – $13.99

CR-V steel beveled edge blades for precision carving.

GREBSTK 4-Piece Wood Chisel Set – $13.98

Sharp bevel edge bench chisels for woodworking.

As an Amazon Associate, we earn from qualifying purchases.

Subscribe for Updates

Get the latest articles delivered to your inbox.

We respect your privacy. Unsubscribe anytime.