How to Finish a Wood Cutting Board

Finishing a wood cutting board involves several careful steps. Each step ensures the cutting board not only looks appealing but is also durable and food-safe. Let’s go through the process, breaking it down into manageable tasks.

Select the Right Wood

The first step is choosing the appropriate wood. Hardwoods are the preferred choice due to their tight grains and durability. Maple, walnut, cherry, and oak are popular options. However, make sure the wood is sustainably sourced and not treated with harmful chemicals. Hardwoods resist scoring and thus, are more hygienic. When selecting a wood type, consider its hardness, grain orientation, and personal aesthetic preferences.

Prepare the Wood Surface

Pursuing a smooth surface is essential. Begin by sanding the board. Start with 80-grit sandpaper to remove rough patches, then progress to 120-grit. Finally, use 220-grit for a smooth finish. Ensure you sand along the wood grain to avoid scratches. Use a tack cloth to remove sawdust remnants. This preparation step sets the foundation for an excellent finish.

Choose the Right Finish

Once the surface is ready, select a suitable finish. Food-safe finishes are paramount for cutting boards. Mineral oil is a popular choice. It’s clear, odorless, tasteless, and safe for food contact. Alternatively, beeswax or a curing oil like walnut oil can be used. Avoid finishes that will turn rancid over time or those not indicated for food contact use. Look for finishes specifically labeled food-safe.

Apply Mineral Oil

Apply a generous amount of mineral oil to the cutting board surface. Use a clean, lint-free cloth or a soft-bristled brush. Ensure the oil is evenly spread across the board. Allow the board to absorb the oil for at least 20 minutes, then wipe off any excess. Repeat this process 2-3 times to ensure deep penetration into the wood fibers. This step enriches the wood and provides a protective barrier against moisture.

Incorporate Beeswax

For additional protection, use a beeswax finish after oiling. Melt a tablespoon of beeswax with four tablespoons of mineral oil in a double boiler. Stir until homogenized. Let the mixture cool slightly until it solidifies to a balm-like consistency. Apply this beeswax mixture using a circular motion with a cloth. Allow it to set for a few hours or preferably overnight. Buff away any residue once the wax has hardened. Beeswax adds a lustrous sheen and enhances water resistance.

Routine Maintenance

Proper upkeep is crucial for longevity. Regularly treat the board with mineral oil every month or so, depending on frequency of use. After each use, wash the board with mild dish soap and warm water. Avoid soaking or putting it in a dishwasher, as it could cause warping and cracking. Make sure to dry the board thoroughly after washing. Store the cutting board in a dry location to prevent moisture damage.

Handle and Storage Tips

A well-maintained cutting board is less likely to harbor bacteria. Always use separate boards for raw meats and vegetables to prevent cross-contamination. When storing, keep the board upright or laid flat to prevent warping. Avoid prolonged exposure to sunlight, which can cause the wood to dry out and crack. Remember that proper handling extends the life of your cutting board significantly.

Resurfacing Old Boards

If your cutting board shows signs of wear, resurfacing can give it new life. Sand away deep cuts or stains using the same method described earlier. Reapply the mineral oil and beeswax finish. This extends the lifespan and keeps the board looking new.

Avoiding Common Mistakes

There are some pitfalls to avoid in this process. Don’t over-saturate the board with oil, as it can cause the wood to swell. Likewise, allowing water to stand on the wood can lead to damage. Ensure any oil or wax used is food-grade quality. Using unsuitable products can contaminate food prepared on the board.

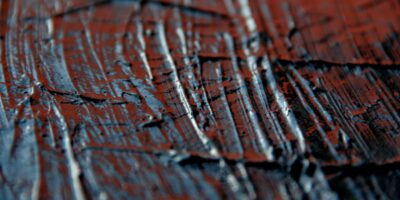

Understanding the Grain

The orientation of the wood grain affects the cutting board’s functionality and longevity. End grain boards show the cross-section of fibers, providing a self-healing surface ideal for heavy chopping. Edge grain boards are more straightforward to manufacture and are often more affordable, making them suitable for general kitchen use. Understanding these differences helps in selecting and maintaining your board effectively.

Final Thoughts on Finishing

Finishing a wood cutting board is part science, part art. Each step, from the choice of wood to the type of finish, contributes to its resilience and visual appeal. Regular maintenance preserves the board’s hygiene and functionality, ensuring it serves you well for years.

“`

Subscribe for Updates

Get the latest articles delivered to your inbox.

We respect your privacy. Unsubscribe anytime.